Global settings English (US) | mm

Languages

Unit

Cancel

Apply

Products

Insert Edge Specification Overview

|

ISO |

Work Material |

Grade |

Standard |

Low Cutting Force Type |

Strong Edge Type |

|||||||||

|

Code |

α |

W |

Honing |

Code |

α |

W |

Honing |

Code |

α |

W |

Honing |

|||

|

H |

Hardened Steel |

TCBH510 |

S01015 |

15° |

0.10 |

Yes |

S01010 |

10° |

0.1 |

Yes |

S01530 |

30° |

0.15 |

Yes |

|

TCBH520 |

S01325 |

25° |

0.13 |

Yes |

S03035 |

35° |

0.30 |

Yes |

||||||

|

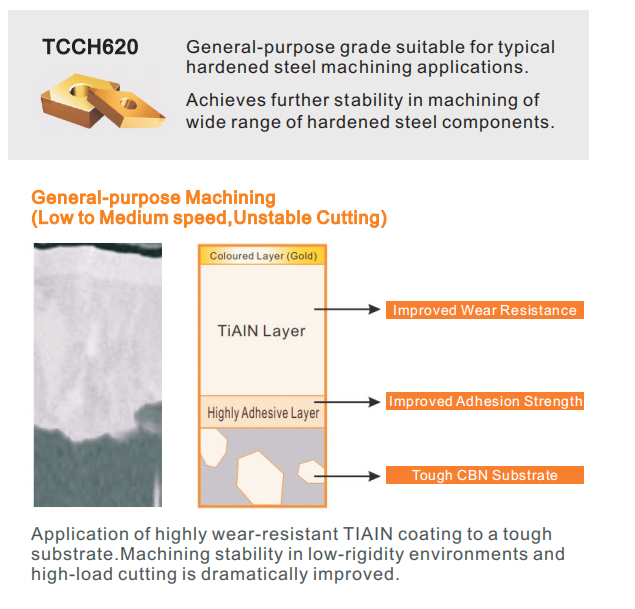

TCCH620 |

||||||||||||||

|

K |

Gray Cast lron |

TCBK100 |

S01520 |

20° |

0.15 |

Yes |

T01015 |

15° |

0.1 |

No |

S01530 |

30° |

0.15 |

Yes |

|

HL |

- |

- |

Yes |

S03035 |

35° |

0.30 |

Yes |

|||||||

|

S |

Sintered Alloy |

TCBX800 |

S01325 |

25° |

0.13 |

Yes |

T01015 |

15° |

0.1 |

No |

S01530 |

30° |

0.15 |

Yes |

|

HL |

- |

- |

Yes |

S03035 |

35° |

0.30 |

Yes |

|||||||

|

Uncoated |

Grade |

CBN |

Grain Size |

Work Material |

Features |

Application |

|

|

TCBH510 |

50 to 55 |

3 |

H |

Hardened Steel |

General-purpose grade for hardened steel machining with a high degree of fracture and wear resistance. |

Bearing Steel |

|

|

TCBH520 |

60 to 65 |

2 |

Hardened Steel |

|

Bearing Steel |

||

|

TCBK100 |

90 to 95 |

2 |

K |

Gray Cast lron |

Grade exhibiting wear and fracture |

Cylinder Block and Head |

|

|

TCBX800 |

90 to 95 |

1 |

S |

Sintered Alloy |

Grade exhibiting improved wear and fracture resistance in cutting of sintered alloy. |

Sintered Parts Valve Seat Ring |

|

|

TCBS700 |

90 to 95 |

4 |

Heat-resistant Alloy |

Provides long tool life in the finishing of Heat-resistant Alloy |

Aerospace Parts |

||

|

coated |

TCCH620 |

65 to 70 |

2 |

H |

Hardened Steel |

Utilising a tough substrate along with a highly wear-resistant and adhesive coating layer, to achieve long tool life in general-purpose to high-efficiency machining. |

Bearing Steel Carburised Steel |

|

ISO |

Work Material |

Grade |

Cutting Condition |

||

|

Vc(m/min) |

f(mm/rev) |

ap(mm) |

|||

|

H |

Mould Steel Hardened Steel (>HRC 45) |

TCBH510/TCBH520 TCBH510/TCBH520 |

90-110 120-250 |

0.1-0.2 0.1-0.5 |

0.1-0.5 0.5-2.5 |

|

Hardened Steel(>HRC 45) |

TCCH620 |

90-110 150-250 |

0.1-0.2 0.1-0.5 |

0.1-0.5 0.5-2.5 |

|

|

K |

Gray Cast lron |

TCBK100 |

400-1500 |

0.1-0.8 |

3.0 |

|

S |

<16%Co Sintered Ni-based Heat-resistant Alloy |

TCBX800 TCBS700 |

20-40 40-100 |

0.1-0.25 0.05-0.2 |

0.1-1.0 0.1-1.0 |