Global settings English (US) | mm

Languages

Unit

Cancel

Apply

Products

1.A generation of G class cermet for steel finishing turning.

2.Cermet grades with remarkable stable tool life due to incredible fracture resistance.

| Chipbreaker | Features | Application | Cutting Edge |

| 15M |

Shallow depth of cut with sharp edge.Longer tool life at high speed cutting due to low cutting force. Good finishing surface. |

|

|

| 15V | Longer tool life due to minimizing chip contact and reducing cutting heat while machining |  |

|

| 12U/13U/15U | Improved chip control makes tool life longer and better machining |  |

|

| 15K |

Excellent chip control in application withmicro depth of cut and low feed. Low cutting load and super finishing surface. Excellent for both internal and external machining |

|

|

| 14VI | Longer tool life due to minimizing chip contact and reducing cutting heat while machining |  |

|

|

ISO |

Operation |

Chipbreaker |

Grade |

ap(mm) |

f(mm/rev) |

Vc(m/min) |

|

P |

Precision |

15V |

TC580 |

0.05-0.20 |

0.01-0.10 |

100-250 |

|

15M |

0.05-0.20 |

0.01-0.10 |

100-250 |

|||

|

15K |

0.05-0.20 |

0.01-0.10 |

100-250 |

|||

|

12U/15U |

0.05-0.20 |

0.01-0.10 |

100-250 |

|||

|

Finishing |

15V |

0.05-2.00 |

0.10-0.30 |

100-250 |

||

|

15M |

0.05-2.00 |

0.10-0.30 |

100-250 |

|||

|

14VI |

0.05-2.00 |

0.10-0.30 |

100-250 |

|||

|

15K |

0.05-2.00 |

0.10-0.30 |

100-250 |

|||

|

12U/15U |

0.05-2.00 |

0.10-0.30 |

100-250 |

|||

|

Medium cutting |

15V |

0.20-2.50 |

0.10-0.30 |

100-250 |

||

|

14VI |

0.20-2.50 |

0.10-0.30 |

100-250 |

|||

|

15K |

0.20-2.50 |

0.10-0.30 |

100-250 |

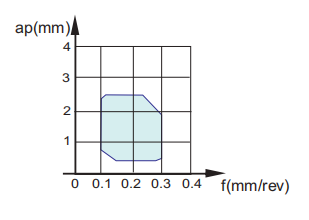

| Workingpiece Type: | Guide pillar |  |

| Work Material: | SCM415 | |

| Inserts: | VBGT110302R-15M | |

| Grade: | TC580 | |

| Cutting Conditions: | VC=125(m/min) |  |

| f=0.15(mm/rev) | ||

| ap=1(mm) | ||

| Cooling From: Wet |