Global settings English (US) | mm

Languages

Unit

Cancel

Apply

Products

1.A generation of PVD grades for heat-resistant alloys turning.

2.Incredible reliability in turning of heat-resistant alloy due to Nano-multi-layered AlTiN coating.

| Chipbreaker | Features | Application | Cuting Edge |

| SF | Large rake angle reduces cutting force.Less burring achieved by diminishing damage from notching. |  |

|

| MP | Exellent chip control when finish cutting.Outstanding chip control when high feed turning at small depth of cut. |  |

|

| GM | Applicable to a wide range of cutting condition with sharp edge.Recommended chipbreaker for stainless steel turning. |  |

|

| MM |

Developed chipbreaker for medium cutting. Excellent chip control due to wide,positive chip flow zone. |

|

|

|

ISO |

Operation |

Chipbreaker |

Grade |

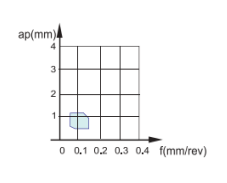

ap(mm) |

f(mm/rev) |

Vc(m/min) |

|

S |

Medium cutting |

SF |

TMS3115 |

0.2-1.2 |

0.05-0.15 |

40-70 |

|

TMS3125 |

45-65 |

|||||

|

GM |

TMS3115 |

0.5-2.0 |

0.05-0.20 |

40-70 |

||

|

TMS3125 |

45-65 |

|||||

|

MP |

TMS3115 |

0.5-2.0 |

0.05-0.20 |

40-70 |

||

|

TMS3125 |

45-65 |

|

ISO |

Operation |

Chipbreaker |

Grade |

ap(mm) |

f(mm/rev) |

Vc(m/min) |

|

S |

Finishing to |

MM |

TMS3115 |

0.5-1.5 |

0.05-0.20 |

40-70 |

|

TMS3125 |

45-65 |

| Workingpiece Type: | Shaft |  |

| Work Material: | 12X18H9T | |

| Inserts: | CNMG120408-MP | |

| Grade: | TMS3115 | |

| Cutting Conditions: | VC=40(m/min) |  |

| f=0.2(mm/rev) | ||

| ap=1(mm) | ||

| Cooling From: Non-Cooling |

| Workingpiece Type: | Shaft |  |

| Work Material: | Inconel 718 | |

| Inserts: | WNMG080408-GM | |

| Grade: | TMS3125 | |

| Cutting Conditions: | VC=45(m/min) |  |

| f=0.25(mm/rev) | ||

| ap=1.0(mm) | ||

| Cooling From:Wet |