Global settings English (US) | mm

Languages

Unit

Cancel

Apply

Products

1.A generation of CVD grades for cast Iron turning

2.Excellent wear resistance and excellent fracture resistance to further improve your machining efficiency.

| Chipbreaker | Features | Application | Cuting Edge |

| MK | Highly reliable chipbreaker for medium cutting under a wide range of conditions from continuous to interrupted cutting.Recommended chipbreaker for cast iron turning. |  |

|

| No Chipbreaker | Can cover a wide range of applications from finishing to roughing of cast iron.Excellent in cutting edge strength. |  |

|

| KR | For heavy cutting of cast iron.The cutting edge has high strength and large chip groove,which is suitable for large allowance cutting. |  |

|

| KS | Highly reliable chipbreaker for medium cutting under a wide range of conditions from continuous to interrupted cutting |  |

|

|

ISO |

Operation |

Chipbreaker |

Grade |

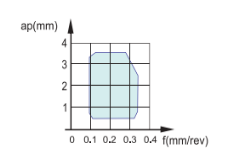

ap(mm) |

f(mm/rev) |

Vc(m/min) |

|

K |

Medium cutting |

No Chipbreaker |

TK910 |

0.5-3.5 |

0.10-0.35 |

200-400 |

|

TK920 |

150-300 |

|||||

|

MK |

TK910 |

0.5-3.5 |

0.10-0.35 |

200-400 |

||

|

TK920 |

150-300 |

|||||

|

Heavy cutting |

KR |

TK910 |

1.0-5.0 |

0.10-0.60 |

200-400 |

|

|

TK920 |

150-300 |

|

ISO |

Operation |

Chipbreaker |

Grade |

ap(mm) |

f(mm/rev) |

Vc(m/min) |

|

K |

Finishing to |

KS |

TK910 |

0.5-3.0 |

0.15-0.40 |

200-400 |

|

TK920 |

150-300 |

| Workingpiece Type: | Auto parts |  |

| Work Material: | Cast lron | |

| Inserts: | WNMGO80408-MK | |

| Grade: | TK910 | |

| Cutting Conditions: | VC=200(m/min) |  |

| f=0.24(mm/rev) | ||

| ap=2(mm) | ||

| Cooling From: Wet |

| Workingpiece Type: | Pipe Joint |  |

| Work Material: | Cast lron | |

| Inserts: | WNMGO80408-MK | |

| Grade: | TK920 | |

| Cutting Conditions: | VC=150(m/min) |  |

| f=0.25-0.27(mm/rev) | ||

| ap=2(mm) | ||

| Cooling From: Wet |