Global settings English (US) | mm

Languages

Unit

Cancel

Apply

Products

1.A generation of PVD first supplement grades for stainless steel turning

2.Excellent wear resistance and excellent fracture resistance to further improve your machining efficiency.

| Chipbreaker | Features | Application | Cutting Edge |

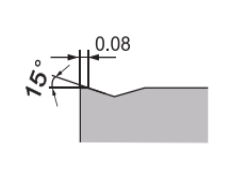

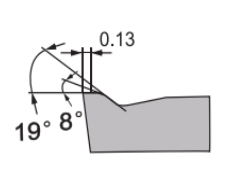

| GF |

Special designed rake angle and cutting edge inclination; Sharp cutting edge,small cutting force; Good machining surface quality; Suitable for stainless steel finishing |

|

|

| TF | 3-dimensional chipbreaker designed with double rake angle;Sharp cutting edge and lower cutting resistance;Efficiently solved build up edge,work hardening and other machining problems.Cutting edge inclination designation is good to control chipflow direction and obtains excellent Surface quality. |  |

|

| QM | Special chipbreaker design to keep cutting edge sharp and safe;Good anti impact resistance;Excellent tool life time;Suitable for stainless steel semi-finishing. |  |

|

| CM | The combined structure of flat edge and edge inclination has both wear resistance and chipping resistance.and can well control the cutting flow,suitable for semi-finishing general machining of steel and stainless steel. |  |

|

|

ISO |

Operation |

Chipbreaker |

Grade |

ap(mm) |

f(mm/rev) |

Vc(m/min) |

|

|

M |

Finishing |

GF |

TG4120 |

0.3-2.5 |

0.05-0.30 |

100-240 |

|

|

|

|||||||

|

TF |

TG4120 |

0.8-2.5 |

0.12-0.35 |

100-240 |

|

||

|

|

|||||||

|

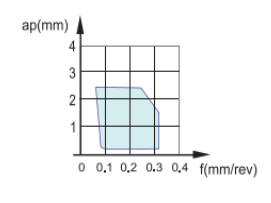

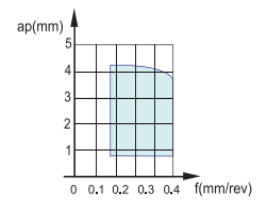

Medium cutting |

QM |

TG4120 |

0.8-4.0 |

0.15-0.40 |

100-240 |

|

|

|

|

|

ISO |

Operation |

Chipbreaker |

Grade |

ap(mm) |

f(mm/rev) |

Vc(m/min) |

|

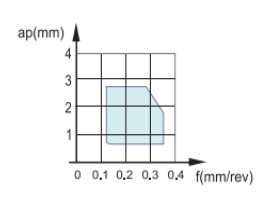

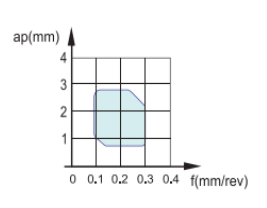

M |

Finishing to |

TF |

TG4120 |

0.5-2.5 |

0.1-0.3 |

100-240 |

|

CM |

TG4120 |

0.8-2.8 |

0.1-0.3 |

100-240 |

||

| Workingpiece Type: | Pipe fitting |  |

| Work Material: | 35-B-T ROCT 1050-2013 | |

| Inserts: | CCMT 060202-TF | |

| Grade: | TG4120 | |

| CuttingConditions: | VC=39.4(m/min) |  |

| f=0.03-0.07(mm/rev) | ||

| ap=0.2(mm) | ||

| Cooling From: Wet |