Global settings English (US) | mm

Languages

Unit

Cancel

Apply

Products

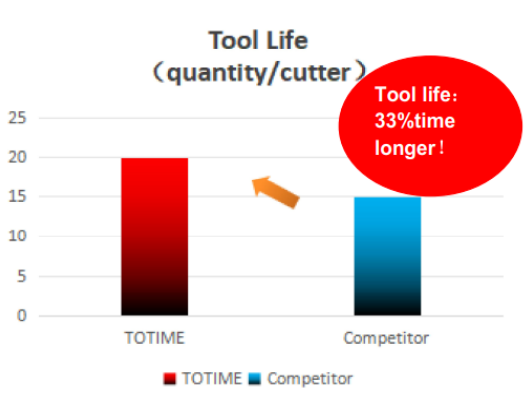

1.A generation of PVD grades for stainless steel turning.

2.Excellent wear resistance and excellent fracture resistance to further improve your machining efficiency.

| Chipbreaker | Features | Application | Cuting Edge |

| MP | Exellent chip control when finish cutting.Outstanding chip control when high feedturning at small depth of cut. |  |

|

| GM | Applicable to a wide range of cutting condition with sharp edge.Recommended chipbreaker for stainless steel turning. |  |

|

| LR | Smooth chipbreaker geometryimproves chip flow with less adhesion.Large curled chips. | |

|

| MM |

Developed chipbreaker for mediumcutting. Excellent chip control due to wide,positive chip flow zone. |

|

|

|

ISO |

Operation |

Chipbreaker |

Grade |

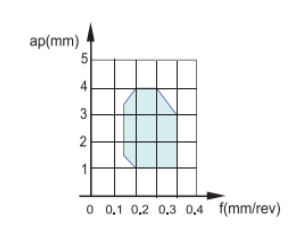

ap(mm) |

f(mm/rev) |

Vc(m/min) |

|

|

M |

Medium cutting |

GM |

TM8110 |

1.0-4.0 |

0.15-0.35 |

100-220 |

|

|

TM8220 |

100-220 |

|

|||||

|

MP |

TM8110 |

1.0-4.0 |

0.15-0.40 |

100-220 |

|

||

|

TM8220 |

100-220 |

|

|||||

|

Heavy cutting |

LR |

TM8110 |

1.5-5.0 |

0.15-0.50 |

100-220 |

|

|

|

TM8220 |

100-220 |

|

|

ISO |

Operation |

Chipbreaker |

Grade |

ap(mm) |

f(mm/rev) |

Vc(m/min) |

|

M |

Finishing to |

MM |

TM8110 |

0.5-2.5 |

0.1-0.3 |

100-220 |

|

TM8220 |

100-220 |

|

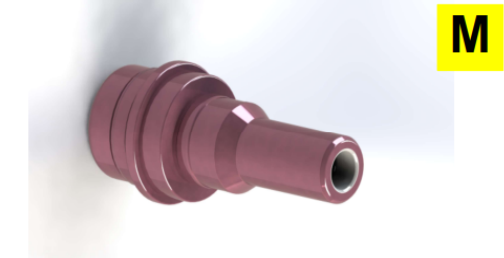

Workingpiece Type: |

Equipment Parts |  |

| Work Material: | SUS304 | |

| Inserts: | DNMG110404-GM | |

| Grade: | TM8110 | |

| Cutting Conditions: | VC=100(m/min) |  |

| f=0.2(mm/rev) | ||

| ap=1.5(mm) | ||

| Cooling From: Wet |

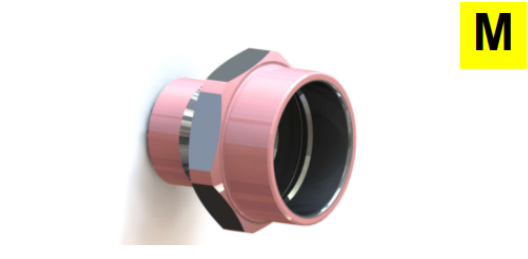

| Workingpiece Type: | Pipe fitting |  |

| Work Material: | SUS316 | |

| Inserts: | DCMTO70202-MM | |

| Grade: | TM8220 | |

| Cutting Conditions: | VC=150(m/min) |  |

| f=0.1(mm/rev) | ||

| ap=0.8(mm) | ||

| Cooling From: Wet |